Trip Indicator Manufacturer & Supplier

Trip Indicator Manufacturer

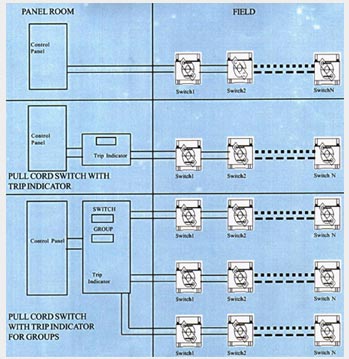

Powertech makes safety switches with Trip Indication & communication cards has solved the problem that arises with traditional safety switches it was difficult to trace the actuated switch as these switches are placed far away from each other as well as from the control room.

Powertech offers these switches with a communication card so that operator can easily locate the actuated switch & can give instructions to the field person accordingly. The card inside these switches is assigned a specific address code.

Operation of the System

The system consists of two-part :

- Trip indicator

- Safety switch with communication card.

Signals from all the field safety switches with communication cards are given to the trip indication unit placed in the control room, whenever a particular switch has operated the receives to the indication systems changes & displays the particular switch on the display of the unit. The Trip Indication unit changes its o/p signal from no to NC whenever any fault condition occurs. This signal is further can take for the interlocking purpose

Advantages Of Conventional System :

- The time required in a manual search for the actuated switch is eliminated.

- Further action can be taken very rapidly

- Grouping is possible

- Trip indicator with fail-safe circuit

- Every Switch will have a specific address code so the actuated switch can be directly displayed

- The system does not require extra PLS i/p

- Interchangeable data address code with the help of held terminal so replacement is easy hence do not

- Require to make inventory for each addressed switch

- Signal cabling can be done by 2-core cable only.

- Communication failure is indicated in the control room & safety is ensured

- Weatherproof switches IP 65

Standard Features :

- No NC contact of PCS can be used and is selectable by the user.

- A scrolling facility is available to scroll no. of operated PCS.

- All operated PCS will be displayed one by one

- Auto reset facility for removing indication reset PCS

- No restriction on the distance between switches and the control room

- Skip channel no. with bypass facility is available

- For cable short or open separate fault reply output option for conveyor tripping

- Grouping is Possible

- Max. No. of PCS is 999 and can be divided into 1 to 4 groups

Please specify the following points to select a proper model:

- No Switches to the interface

- No of Groups.

- Length of conveyor/cable.

Operation :

The pull cord switch is mounted on the walkway side of the conveyor belt, preferably at about every 20-25 meters. When the rope is pulled from any side. The switch gets operated. Unless and until the handle is reset to normal position manually, the switch remains in operating condition. Pull Rope switch All the Pull Cord Switches installed along an individual belt are electrically wired in series and connected to the control station by a two-core cable. Therefore actuation of any one of these Pull Cord Switches will stop the concerned conveyor until the particular switch is manually reset.

Pull Cord Wire / Rope and Typing Accessories :

Pull cord wire, Dia. Approx. 5 – 6 mm, 6 x 7 construction, galvanized steel wire with PVC cover. Specially extruded for the material handling industry.

Tying clips, Cable Guide, Eye Bolt, Tension Spring, and Cable Gland for tying pull cord cables to individual switches are also supplied at extra cost.

Related Products

Trip Indicator Manufacturer & Supplier in Nashik, India

Sales Area :

- Indonesia |

- Malaysia |

- Saudi Arabia |

- Oman |

- Nigeria |

- Tanzania |

- Uganda |

- Kenya |

- South Africa |

- Egypt |

- Mauritius |

- Peru |

- Jharkhand |

- Tamilnadu |

- Andhra Pradesh |

- Telangana |

- Karnataka |

- Gujarat |

- Madhya Pradesh |

- Uttar Pradesh |

- Goa |